Radian Audio Engineering on Voice Coil Test Bench

January 27, 2020

2 min read

For the February 2020 edition of Voice Coil magazine, Vance Dickason characterizes the Radian 835PB ferrite compression driver.

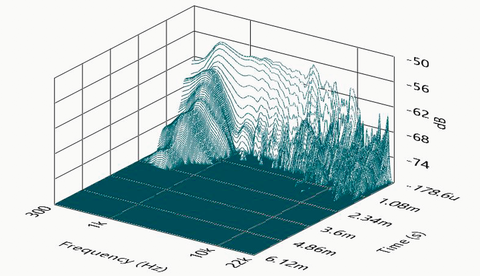

Radian 835BP SoundCheck CSD waterfall plot.

If you are familiar with Radian’s compression drivers, or have read some of the past explications about Radian’s neodymium compression drivers, the 835PB has the expected rich feature set of other Radian compression drivers. This includes a 1.4” throat diameter, a 190 mm × 190 mm ferrite magnet motor, high temperature 76.2 mm (3”) diameter polyimide voice coil former with a copper clad aluminum edge wound ribbon wire voice coil, a self-aligning field replaceable diaphragm assembly, and the most important feature, a proprietary processed and hardened aerospace grade aluminum alloy diaphragm over a three-slit phase plug. The driver has color-coded gold-plated push terminals and a net weight of 14.6 lbs.

Renowned for its mastery of diaphragms, compression drivers and coaxial loudspeakers, with the 835PB, Radian Audio shows how the company continues to offer excellent performance in a fairly high power handling package (200 W continuous power handling - 100 W AES2 Rev. 2003). The 835BP is also available with a beryllium diaphragm.

From the test measurements, the 835PB 1.4” ferrite compression driver displays excellent performance in a fairly high power handling package (200 W continuous [3 dB higher than the AES power rating]), and a ferrite motor compression driver build quality that is on par with the best players in this industry.

Voice Coil magazine is free for loudspeaker industry professionals.

Also in Articles

August 17, 2024

2 min read

In his Test Bench series of driver characterizations for Voice Coil magazine, Vance Dickason measured the LM10n, the latest and larger sized planar ribbon driver from Radian Audio Engineering. The measurements clearly show why the LM10n is a unique planar that can be used as a very high quality midrange with the latest LT2.2 or LT3.2 high frequency planar ribbons, or as a wide range (120Hz to 20kHz) dipole or monopole transducer. The full article is now available online.

Read More

November 14, 2020

2 min read

In its August 2020 edition's Voice Coil magazine focuses once more on the new-generation of our LT Series of FEA optimized Planar Ribbon drivers. Vance Dickason's famous Test Bench characterizations are widely regarded in the audio industry as an accepted benchmark for independent speaker measurements, and he did indeed serve a generous dose of measurements for our LT2 Ribbon Transducer and corresponding waveguide. The full article and measurements are now available online in full!

Read More

October 24, 2020

3 min read

Igor Levitsky is highly recognized in the audio industry for developing some of the best planar magnetic speaker and headphone drivers for some of the most reputed brands, focusing precisely on this type of technology. Igor worked with Radian Audio Engineering in the development of the latest generation LT Series of planar ribbon drivers, reflecting the latest manufacturing techniques and materials.

Read More